Overview

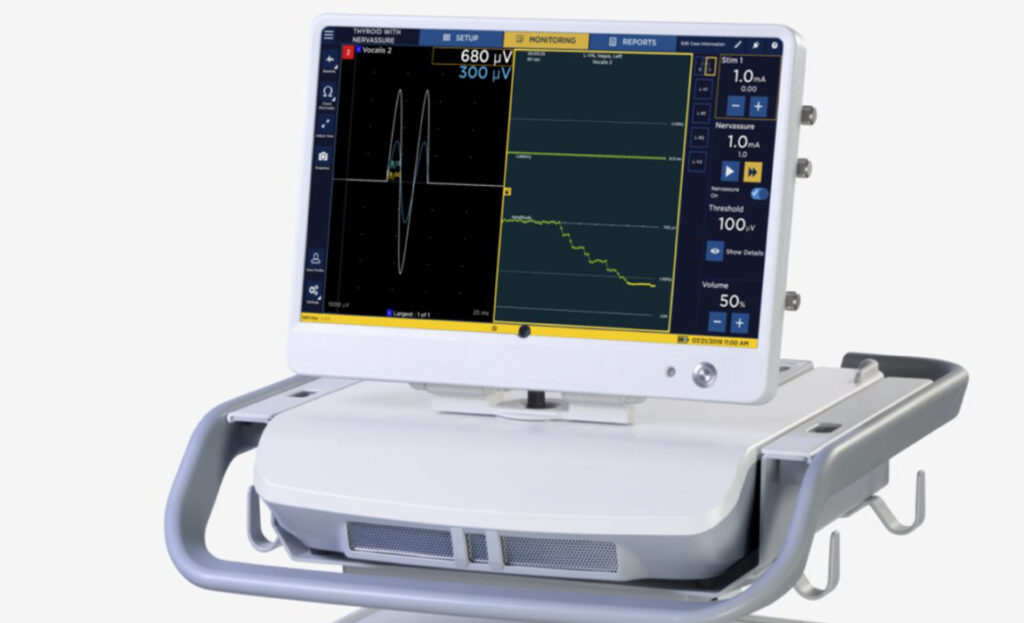

The customer needed to refresh their aging nerve induction platform. The refresh from version 3.0 to 4.0 required integrating new technology into the platform, managing a staggered rollout of V4.0 and obsolescence of 3.0 based on geographic markets, and maintaining regulatory compliance on both products throughout.

Solution

MPE concurrently managed 3.0 production and 4.0 design and development, while leveraging our QMS and document control systems for both versions. MPE tooled custom components to accelerate and de-risk the launch of the new product. The customer transitioned the new 4.0 to MPE’s 3PL service.

Result

V4.0 received 510(k) clearance on the first application. MPE continues to manage v3.0 after v4.0 launch, and seamlessly ramps up and down production of each according to specific market demands and regulatory rollout. MPE is also managing end-of-life planning for v3.0, avoiding costs increase due to reduced volumes and creating service parts to meet long-term needs. The customer realized a lower TCO through MPE’s 3PL services and by relying on MPE to manage both products through the transition.

Increased Revenue

Accelerated time to market via efficiencies stemming from a single partner.

Lower Cost

Limited development cost by avoiding handoffs and resets. Lower ongoing TCO through operational efficiencies in product delivery.

Lower Risk

Reduce product delivery disruption due to design changes. Reduce the risk of new product market launch (timing/design). Reduce regulatory risk via revision.