Overview

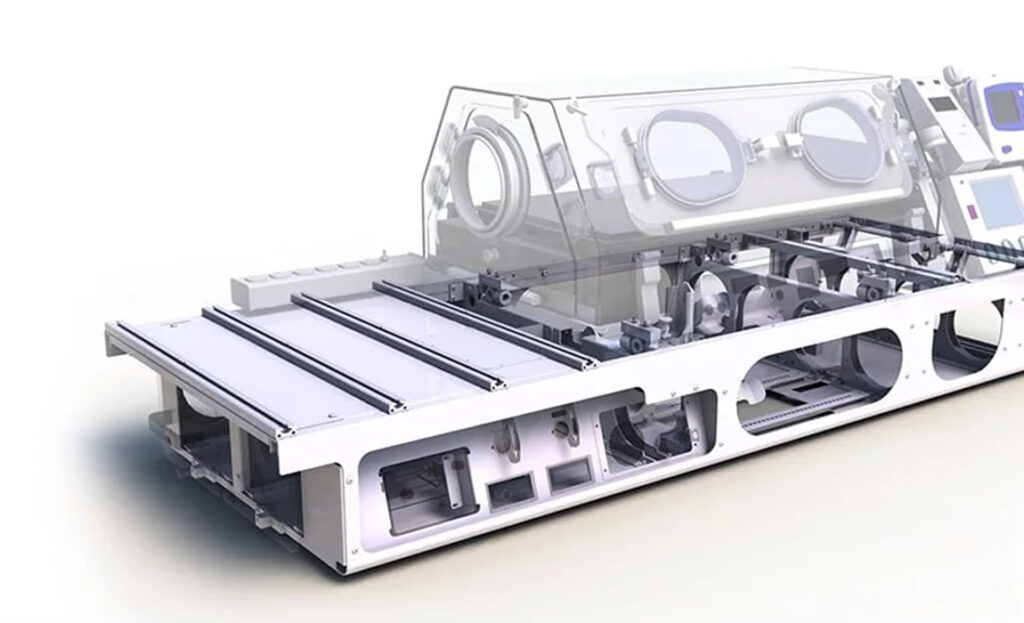

Efficiency and reliability are just two of the vital needs in the equipment used when dealing with lifesaving ambulatory care of an infant. That pressure increases with need for air transport.

Challenge

In order to seamlessly interface existing trolleys and maintain a high level of configuration to critical devices and accessories, MPE’s multidisciplinary team approached the comprehensive design process with calculation. With the wide-ranging list of product constraints and the harsh environmental conditions that the mobile neodevelop new manufacturing processes for the framework that guaranteed reliability and durability under the extreme conditions of both ground and air ambulatory transportation carenatal intensive care system would be exposed to, during such a situation, the team conducted in-depth research to develop the structural design.

Process and Solution

Extensive and iterative prototypes were used to perform structural analysis of the designs and in vetting of materials. The data led the team to develop new manufacturing processes for the framework that guaranteed reliability and durability under the extreme conditions of both ground and air ambulatory transportation care.

Rigorous FEA and physical testing proved the device to meet and/or exceed the following air and ground requirements: EN 1789:2007, EN ISO 10993-1:20096, Federal Aviation Regulations (FAR) and Canadian Air Regulations (CAR) – FAR 23/CAR 523 and FAR 29/CAR 529.