As we advance into a value-based healthcare system, the need for high-quality and complex component parts for capital medical equipment increases.

These parts are often required in significant quantities and must meet strict regulations, which can cause delays when relying on outdated stamping processes. To address these needs and meet modern demands, many MedTech OEMs turned to CMOs (Contract Manufacturing Organizations) or CDMOs (Contract Design and Manufacturing Organizations) with modern progressive stamping capabilities.

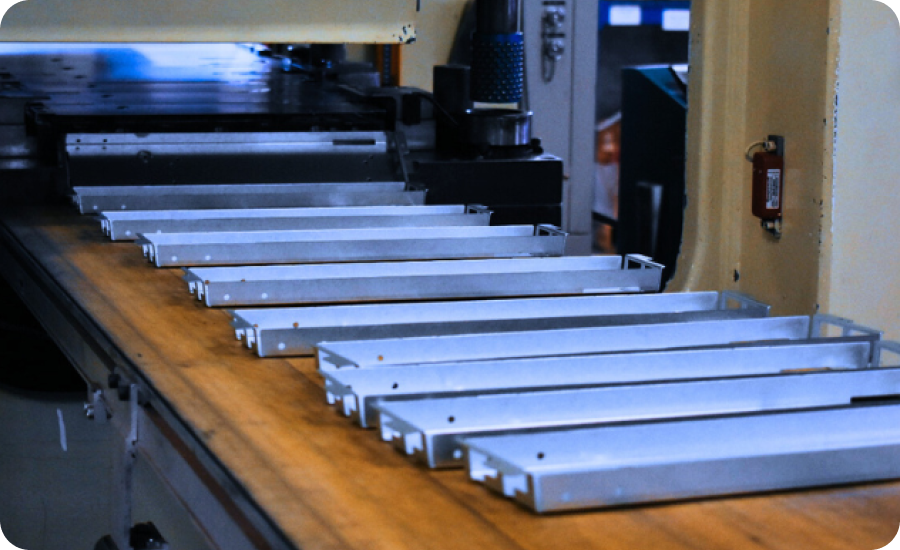

Progressive stamping is a manufacturing process that uses a specialized tool and die sets to create complex shapes and designs in metal. This technique enables medical equipment manufacturers to produce larger volumes of components at a faster rate while reducing the amount of scrap metal generated.

Progressive stamping is efficient for many manufacturing operations that need high quantities of complex components.

Since introducing this manufacturing solution, many OEMs have outsourced their progressive stamping to overseas manufacturers. However, the disruptions caused by the COVID-19 pandemic uncovered how fragile the manufacturing process is for the completion of medical equipment and how detrimental delays or errors in products are in market adoption.

With these risks in mind, MedTech OEMs have started seeing the benefits of partnering with an onshore, vertically integrated CDMO that has progressive stamping capabilities in-house.

In fact, according to Kearny’s 2022 Reshoring Index, surveys ran amongst manufacturing executives and CEOs indicated that more than 80% of companies across all industries are now on a path to reshore at least part of their operations in the next 3 years.

Here are some ways that onshoring your progressive stamping to a vertically integrated CDMO can support your operations and get your product to market.

1. Lower Costs

Although offshoring progressive stamping may seem like the cheaper and more efficient option, studies have shown that’s not always the case. Many offshore progressive stampers will have hidden prices associated with material sourcing, transitions between component type, and transportation of finished goods.

By partnering with a vertically integrated CDMO that has in-house raw materials, and multiple operations to stamp multiple components comes with man cost benefits. Often, costs associated with transportation of materials, the relation of materials from multiple sources, and more are significantly reduced.

2. Better Quality Control

By maintaining complete oversight of the entire production cycle, from raw materials sourcing to final product inspection, manufacturers can closely monitor each stage for compliance with stringent quality standards. This level of control minimizes the risk of defects or inconsistencies in the final output.

A survey done by Reshoring Institute found that 60% of companies that have reshored their operations have seen quality improvements.

With onshore progressive stamping and manufacturing working hand in hand, manufacturers can implement real-time quality checks at various stages of production. This proactive approach allows for immediate identification and rectification of any issues that may arise.

As a result, potential defects are caught early rather than discovered later in the supply chain or by end-users— which is especially critical for capital medical equipment.

3. Quicker Time to Market

Complete oversight over equipment component production is an advantage for CDMOs and commercialization partners. When onshore manufacturers are vertically integrated, they can offer a complete range of services from design to manufacturing to kanban storing, all under one roof.

This kind of setup is beneficial for clients and for ensuring that products can be ready for quicker market adoption.

Overall, the integration of progressive stamping is a necessary step for MedTech OEMs to meet the market’s demands and to provide their customers with the equipment they need.

By partnering with an experienced vertically integrated CDMO that has progressive stamping capabilities, manufacturers can ensure that their complex components are produced with the highest quality standards while reducing costs, and increasing the product’s time to market.