In the ever-changing world of healthcare and medical equipment design, original equipment manufacturers (OEMs) face multiple challenges when bringing products to market.

One of the main concerns for OEM supply chain teams is maintaining consistent quality standards that align with the requirements of key opinion leaders (KOLs) and value analysis committees (VACs). These struggles are often due to a disconnect between product design, development, and manufacturing, hindering the ability to meet these standards and requirements.

As a result of the disconnect between the traditional and siloed process of design, development and manufacturing, supply chain teams struggle to ensure smooth information flow, resource availability, and material distribution. This can lead to production delays, bottlenecks, and a lack of support from KOLs and VACs.

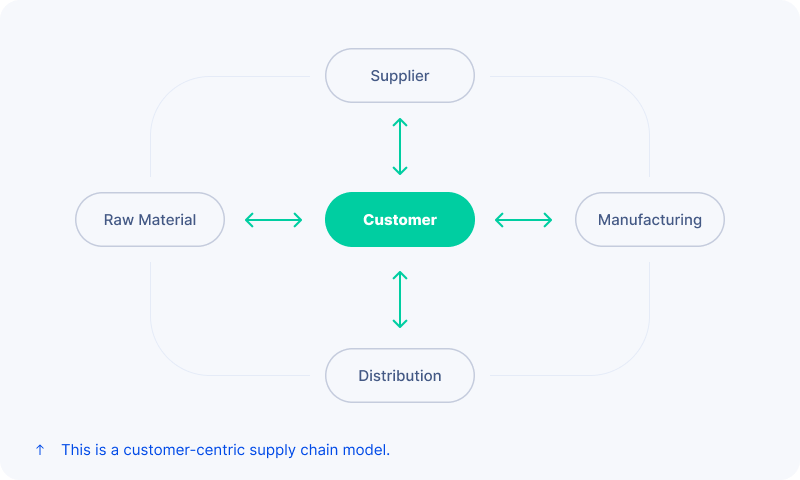

To overcome these challenges, many OEMs and start-ups are realizing the benefits of partnering with a design, development, and manufacturing platform that is a true partner with capabilities to handle the entire process – including supply chain management. They seek a partner with a customer-centric supply chain approach that is internally aligned and integrated into their program.

The Top 5 benefits of Working with a Design, Development and Manufacturing Partner Backed by a Customer-centric and Integrated Supply Chain Team

1. Seamless Operations from Design to Development

An integrated supply chain team ensures a smooth flow of information, requirements, and resources by closely collaborating with the OEM’s product design and development teams.

This collaboration allows for early engagement, valuable input on manufacturability, sourcing strategies, and logistics considerations. It results in a streamlined transition from concept to production, minimizing delays and optimizing operational efficiency.

In fact, according to Gartner research, enabled customers are 2x as likely to repurchase.

2. Enhanced Quality in a Value-Based Healthcare System

A customer-centric and integrated supply chain team prioritizes quality throughout the product design and manufacturing journey. They align their processes with rigorous regulatory requirements and industry standards by working closely with the OEM’s quality assurance and engineering teams.

This integration ensures that quality considerations are addressed from supplier selection to final product inspection, ultimately enhancing product reliability and patient safety.

3. Improved Innovation for Capital Medical Equipment

By collaborating with product development, R&D teams, and supply chain experts, a customer-centric supply chain team provides valuable market insights and contributes to innovative sourcing strategies, materials, and manufacturing techniques.

This early involvement and alignment with the OEM’s vision result in optimized costs and improved time-to-market for groundbreaking capital medical equipment.

Many OEMs and start-ups are realizing the benefits of partnering with a contract development and manufacturing organization.

4. Cost Optimization Across Suppliers

Through close collaboration with finance and procurement teams, the supply chain can employ a holistic approach to cost management. Leveraging their supplier network, they negotiate favorable terms and optimize sourcing and procurement strategies to achieve competitive pricing for raw materials and components.

This approach enables cost optimization without compromising quality or customer satisfaction.

An Accenture study soon following the COVID-19 Pandemic states, “a customer-centric supply chain makes companies a triple P&L threat. They [companies] can boost revenue by as much as 5%. They can reduce cost-of-goods-sold by 3 to 5% and SG&A by 15%.”

5. Overall Customer Satisfaction: From OEMs to Patients

By aligning their operations, goals, and processes with the OEM’s vision and customer expectations, aligned supply chain teams contribute to delivering high-quality products on time. Effective communication and feedback loops foster strong relationships based on trust and transparency, resulting in enhanced customer satisfaction, loyalty, and a positive reputation for the OEM.

Choosing a partner with a customer-centric approach and a unified supply chain team brings significant benefits to OEMs in the MedTech industry. This collaboration ensures seamless operations, enhanced quality, improved innovation, cost optimization, and overall customer satisfaction. With the right partner, OEMs can confidently overcome the challenges of product design and development, successfully bring high-quality capital medical equipment to market, and ultimately improve patient care worldwide.

By aligning their operations, goals, and processes with the OEM’s vision and customer expectations, aligned supply chain teams contribute to delivering high-quality products on time. Effective communication and feedback loops foster strong relationships based on trust and transparency, resulting in enhanced customer satisfaction, loyalty, and a positive reputation for the OEM.

Choosing a design, development and manufacturing partner with a customer-centric approach and a unified supply chain team brings significant benefits to OEMs in the MedTech industry. This collaboration ensures seamless operations, enhanced quality, improved innovation, cost optimization, and overall customer satisfaction. With the right partner, OEMs can confidently overcome the challenges of product design and development, successfully bring high-quality capital medical equipment to market, and ultimately improve patient care worldwide.